One of the more pleasing parts about automation is developing systems that save customers money. This is one of those products. For details read below.

What is it?

Data acquisition systems are designed to collect specific pieces of data from the production process and sometime that data is even used in real-time to affect the quality of various process. The systems currently being sold by The Robot Guy are used in this manner. In addition, the data captured from the production process is stored and can be used in making important decisions regarding the plant processes and material handling. As it is commonly said, the first step to improving is knowing what your doing wrong (or right in many cases).

What does it do?

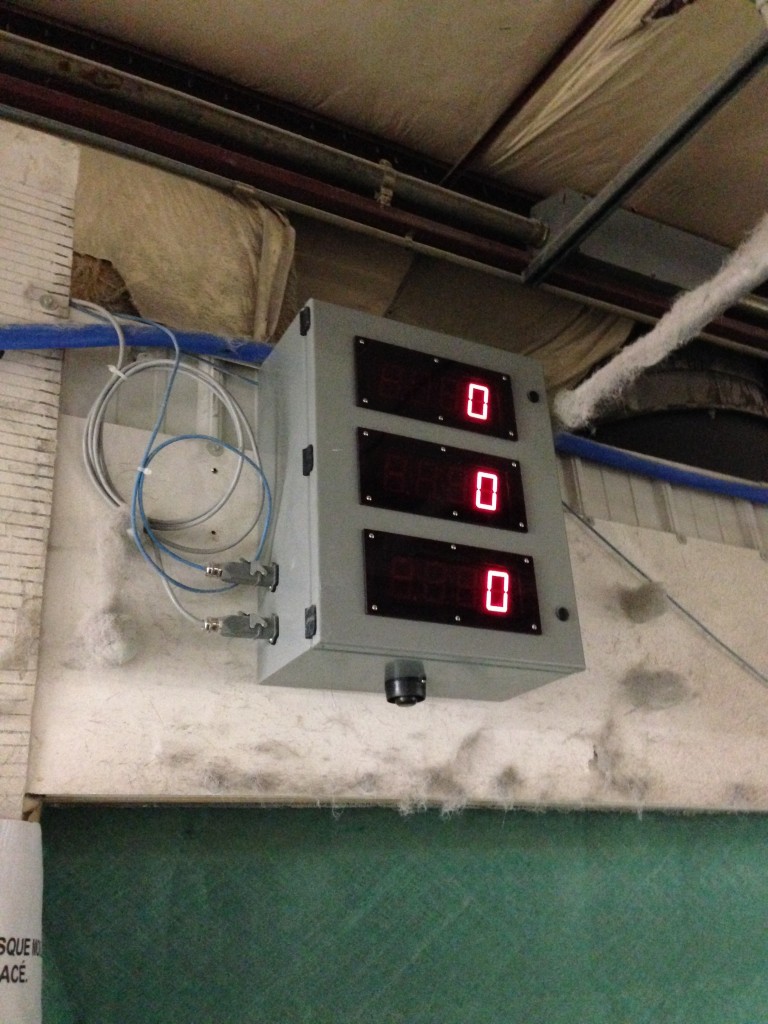

This system is unique because it can be customized in many different ways. The core of the system are process and display units that can accept data from various forms of meters. In the CHOP systems the glass can be tracked externally by reading the air to the chop gun or by a physical reading of glass running over a resolving wheel. Both systems have their drawbacks and advantages.

The fluids can be tracked by either Coriolis meter, positive displacement meter, or even stroke counters. In fact, the list of meters that can be used are almost endless since we just need a pulse/square wave signal back that is proportional to the fluid flow.

The RFID portion of the system is for the real-time data and mold-specific tracking. A mold is scanned before it is sprayed out and that mold’s tag will be tied to data about how much material needs to be palced on the mold. The operator will have a heads-up display tracking their part and can be more accurate knowing exactly how much they are spraying. Once finished, that mold and it’s material usage information is saved so that the production data can be compared to the desired usage data.

Why do I need one?

Since one of the largest cost in any fiberglass operation is in the resin and chop it is imperative that managers and supervisors have a way to track and record usage, as well as have a way to give real-time information to the operators so they can apply the appropriate amounts to each mold, and the more a manufacturer can reign in material costs the less it costs to produce that same part. However, the first step is knowing what you are using in real numbers. This system will do that.

Various parts

For more information and questions about customizing to your needs just click on the CONTACT tab of the website.